Today we’d like to introduce you to Rodney Nelson.

Hi Rodney, it’s an honor to have you on the platform. Thanks for taking the time to share your story with us – to start maybe you can share some of your backstory with our readers?

Initially, my career began as a pitcher for the Kansas City Royals. I had a brief stay in the minor leagues. While competing In the Gulf coast league I did receive some All-star honors. I also received an invite from the organization to their Instructional League in Florida some time before that. At one time I actually was a prospect & projected to be a starter in the majors for that organization. It was a blessing to have shared the field with a special group of guys during that time. After a series of bad choices & not being prepared for the challenges, I would face. The best outcome as far as professional sports would not happen. As for my career in HMI systems , crane operations and technical support at Tenaris, it would be timing, good work ethic and being amongst the right people that would give me that opportunity. Being led into that field of work, but not knowing where it would actually land me was surely a blessing from God. I can also refer back to my high school & early college years to those curriculums that enabled me to do the job today. Although we take many classes & instructions in our field, dealing with computer basics and technicals, a foundation is still needed to move ahead.

Would you say it’s been a smooth road, and if not what are some of the biggest challenges you’ve faced along the way?

There will always be obstacles. The obstacles come with the choices you make. Mentally we have to create a state of mind and a thought process that’s to our advantage & that yields gains on a personal level. Whatever your growth is, if it’s doing just that, it’s a plus in your favor. Career-wise for me we’re speaking of operational as far as heavy machinery, being able to understand isometric drawings and now moving to a more technical field. Whereas your majority or main focus is diagnosis of problems & repairs technically. Making adjustments as needed. The mental capacity to react abruptly as problems occur in a timely manner. Manual movements are to be used as less as possible, but cannot be factored completely out. Some tasks solely call for that specific action. We are dealing with Tenaris’s first state of the art facility and it’s the world’s largest & most automated seamless pipe plant to date. Internally they like to say we’re the flagship to all the other facilities around the world at this point. Every day is full of information & situations. Multitasking and troubleshooting is of the essence. Overall I feel we’ve been successful in our endeavors.

Alright, so let’s switch gears a bit and talk business. What should we know about your work?

Skill sets would be working with HMI Systems, Crane Operations, Industrial processes, Network management, technicals & Tenaris Processes at present. . Before These transitions took place I was in heavy equipment operations dealing with excavations & elevations for some time. I also spent time pipe-fitting for various projects including Tenaris on the new construction side of things.

My experiences in most recent years have been within the energy industry, with additions . Work stemming from the foundations and assemblies of industrial gas facilities (oxygen, hydrogen, nitrogen), methane gas energy projects , natural gas power plants & most recently being employed by Tenaris. I also have a passion for marketing, promotions & coordinating events. I’ve been involved in that for long as I can remember. Now Im a part of a manufacturing process to create seamless pipe for the oil and gas industry.

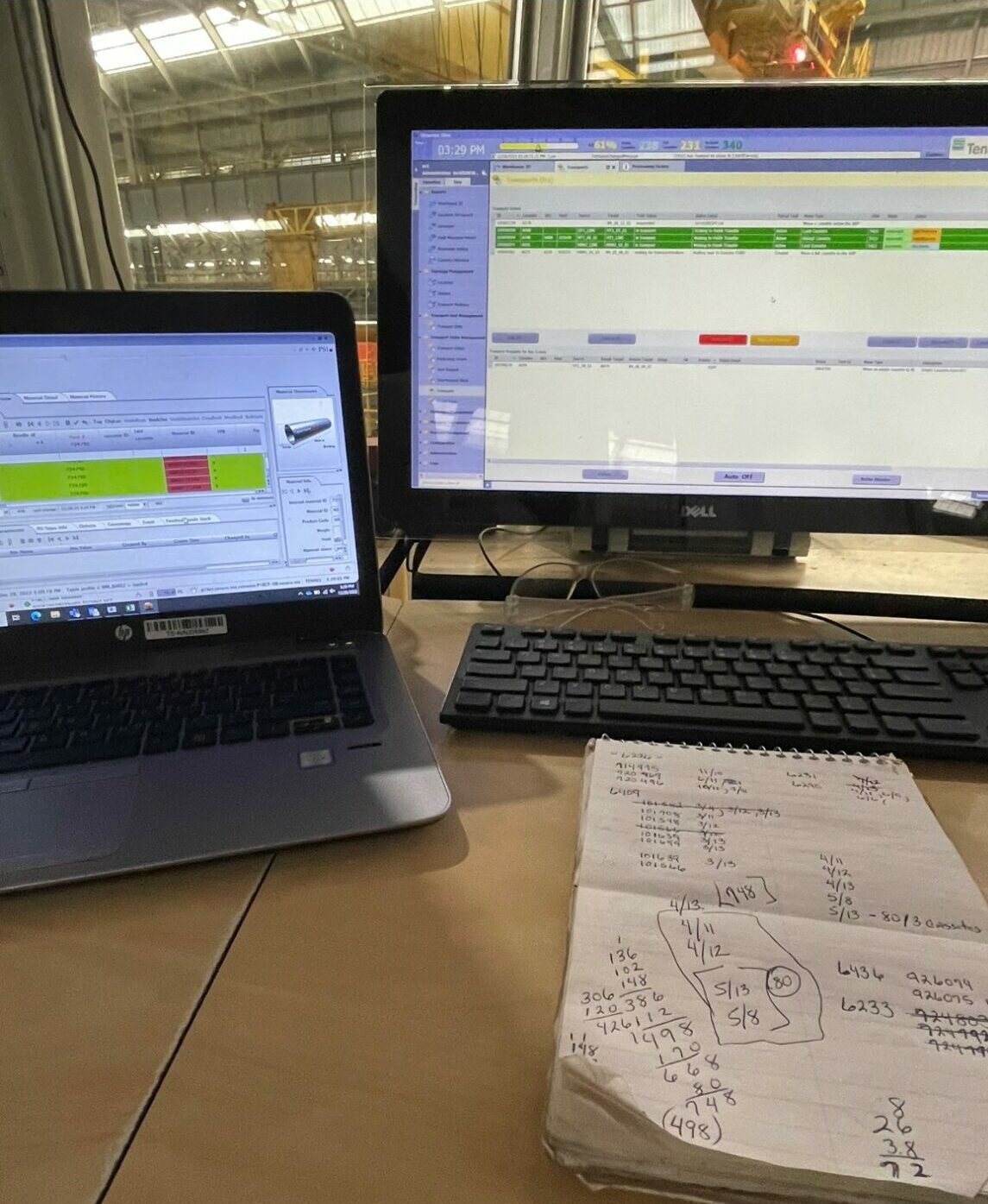

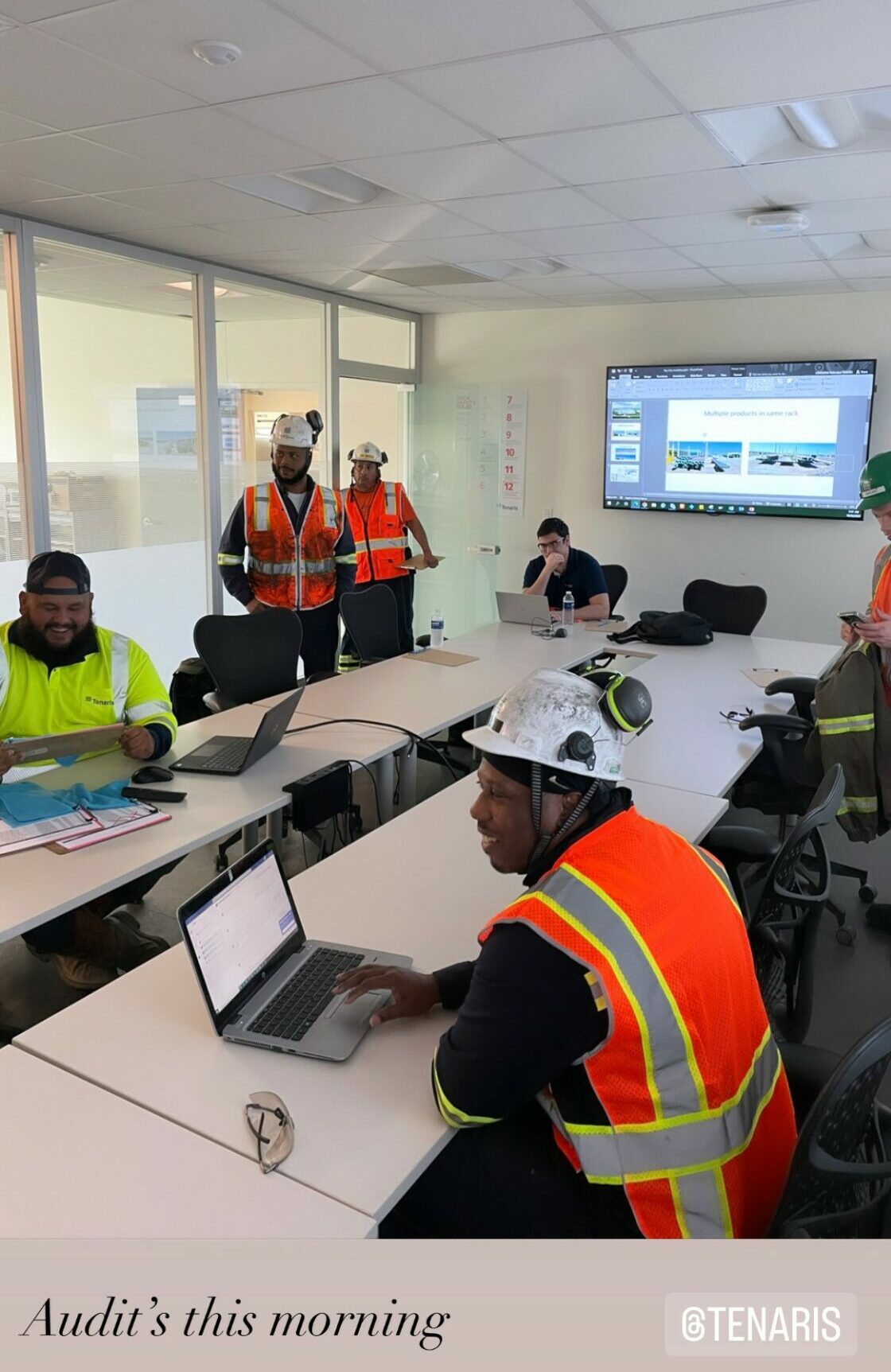

I like to say that we’re the catalyst to the certain processes that go on within the WIP at Tenaris. Whether it’s heat treat, finishing, hot-rolling mill or supply chain. We create a consistent & timely culture in order to get our team the specific materials needed in position for the next process to take place. Were moving materials that can weigh from 2,000 to 80,000 pounds in an automated cycle of nature environment. Safety definitely is first and foremost. Being attentive is a must. We also manage these materials within an online network consistently tracking and relocated these materials virtually as needed. These tasks are made capable by understanding the use of a Siemens digital platform. There’s plenty of classes your consistently attending that will keep you up to speed safety, knowledge & growth-wise.

I didn’t bring myself this far, God did. A friend of mine once said, “It’s no fun until your doing things right”. So I’ll continue with His plan and keep evolving spiritually, as a person and within my craft. I’ll continue to believe, combined with faith & works, to accomplish to the fullest extent of what I possibly can. That’s the plan

Contact Info:

- Instagram: _original_b_o_b

- Facebook: Rodney Nelson

Image Credits

Image Credits

Tenaris Town Hall meetings. Tenaris Pulpit Work station.